With excellent capabilities in the development of automation equipment, Hongyi can quickly build customized, flexible, and high-precision automated production lines based on the characteristics of customer's products and production capacity requirements. Hongyi can quickly develop mass production process and testing plans, supporting the rapid mass production and market launch of customer's products.

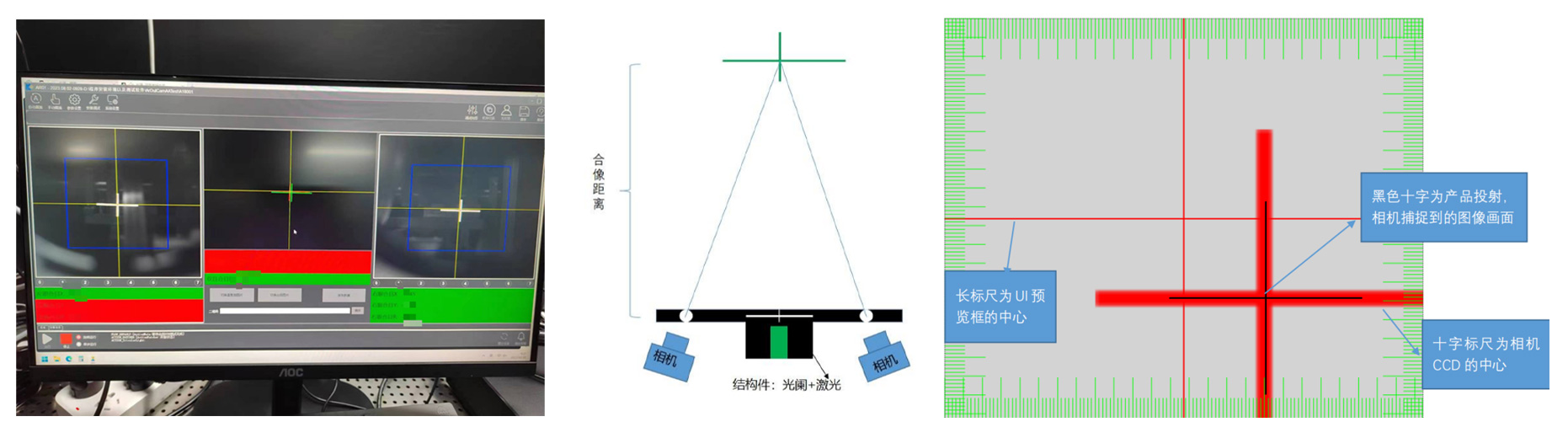

Hongyi designs and utilizes a series of automated processing equipment and tools, achieving low-cost and high-efficiency manufacturing capabilities. The diagram shows the operation status of some automated equipment.